300 kHz Ultrasonic Sensor will be exhibited at the Consumer Electronics Show (CES) in Las Vegas, USA.

Consumer Electronics Show (CES)

Dates: January 6–9, 2026

Location: Las Vegas, USA

Booth Number: North Hall 10529

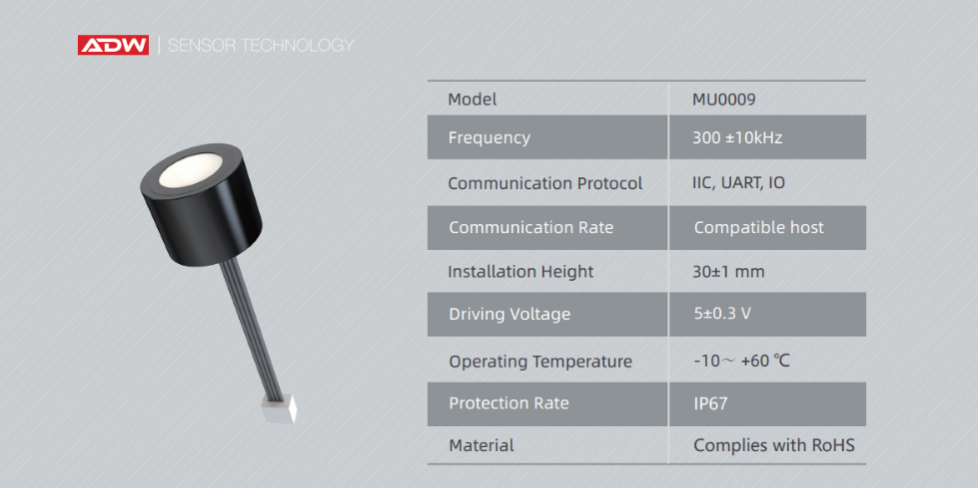

Ultrasonic sensing technology continues to evolve, with higher frequencies unlocking new capabilities. The 300 kHz ultrasonic sensor, leveraging high-frequency ultrasonic waves, stands out for its ability to effectively identify different materials, offering significant advantages over conventional sensors for specialized applications.

Enhanced Performance Through High Frequency

Operating at 300 kHz, this sensor utilizes a much shorter wavelength than standard low-frequency ultrasonic sensors. This fundamental characteristic grants it two key performance benefits:

Improved Penetration Capability: The high-frequency, focused energy beam demonstrates superior ability to penetrate certain mediums and detect fine surface variations or underlying layers that lower-frequency waves might miss.

Higher Detection Accuracy: The short wavelength allows for exceptional resolution, enabling the sensor to discern minute details, thickness differences, and subtle material boundaries with high precision.

Core Application: Intelligent Material Identification

This combination of penetration and accuracy makes the 300 kHz sensor ideal for systems requiring material discrimination. A prime example is in sweeping robots. Here, the sensor can be integrated into a material identification system to distinguish between hard flooring (tile, wood), soft carpets, and potential obstacles. This allows the robot to automatically adjust suction power, brush height, or navigation strategy, optimizing cleaning efficiency and protecting both the machine and floor surfaces.

Critical Role in Media Handling and Verification

Beyond material identification, the sensor's precision is critical for reliable media handling in various office and financial equipment:

Double Sheet Detection & Paper Counting: In printing machines, scanners, and ATM machines, ensuring that only a single sheet is fed at a time is crucial to prevent jams, misprints, or dispensing errors. The 300 kHz sensor can accurately detect the presence of multiple sheets (double or multi-feeds) by measuring the combined thickness or acoustic signature with high sensitivity. Simultaneously, its rapid response enables precise paper counting for batch jobs or transaction logging.

Quality Control: The technology can also be extended to check for material defects, wrinkles, or incorrect media type in automated feed systems.

Conclusion

The 300 kHz ultrasonic sensor represents a specialized advancement in sensing technology. By delivering improved penetration and superior accuracy, it solves complex challenges in material identification and precise media detection. Its adoption in intelligent cleaning devices and critical paper-handling equipment underscores its value in enhancing automation, preventing errors, and ensuring operational reliability across diverse industries.