Vortex Flow Sensor exhibited at the Consumer Electronics Show (CES) in Las Vegas, USA.

Consumer Electronics Show (CES)

Dates: January 6–9, 2026

Location: Las Vegas, USA

Booth Number: North Hall 10529

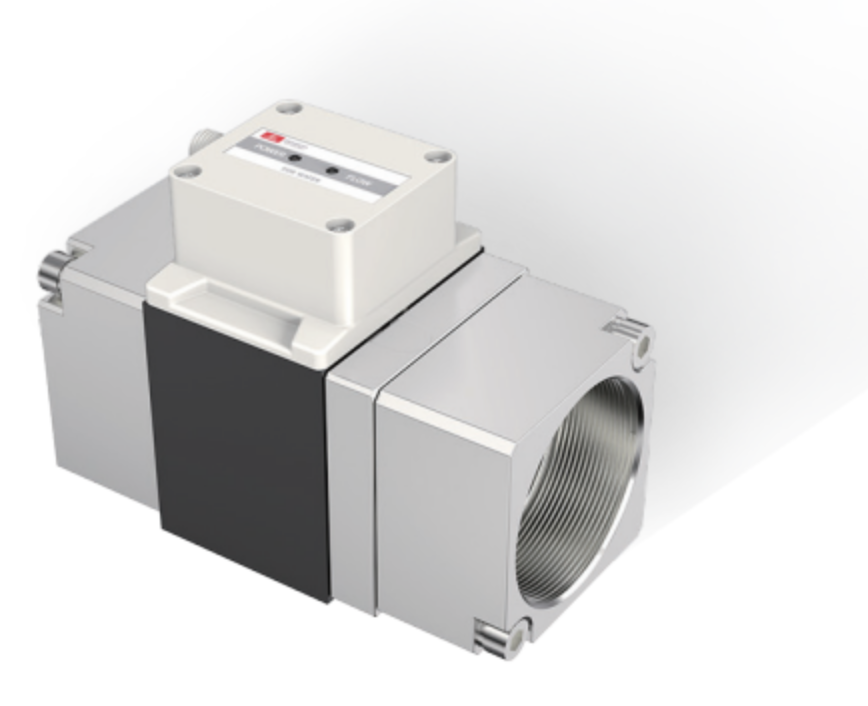

Accurate and reliable liquid flow measurement is essential for process control, resource management, and system efficiency across numerous industries. The ADW FV series vortex flow sensors provide a robust solution based on the well-established Kármán vortex street principle, delivering high-performance flow data with exceptional versatility through a modular design.

Operating Principle: Harnessing the Kármán Vortex Effect

The core of the sensor's operation lies in fluid dynamics. As the fluid medium flows through a precisely engineered bluff body (vortex generator), it separates and creates a repeating pattern of regular vortices that shed alternately from each side. The frequency of this vortex shedding is directly proportional to the velocity of the fluid. A high-sensitivity piezoelectric transducer receiver detects the minute pressure fluctuations caused by each shedding vortex and converts this frequency into a raw electrical signal. This signal is then conditioned by a differential amplifier and filter circuit, processed, calibrated, and finally output as a precise fluid velocity reading. Combining this velocity with the pipe's cross-sectional area yields volumetric flow rate.

Modular Design for Customized Solutions

The ADW FV sensor is engineered for flexibility. Its primary system consists of the flow pipe, vortex generator, piezoelectric transducer receiver, and core signal processing module. Beyond this foundation, the sensor supports various optional modules that can be seamlessly integrated to meet specific application needs:

Temperature Module: For temperature-compensated mass flow calculation.

Display Module: For local, real-time readout of flow data.

Pipe Section Joint Module: For easy installation and adaptation to different piping systems.

Communication Output Module: Offering variable outputs such as voltage, current, or RS-485 digital communication.

Key Performance Advantages

This design translates into significant benefits for end-users:

High Measurement Accuracy: Delivers reliable performance with an accuracy of ±3% of Full Scale (F.S.).

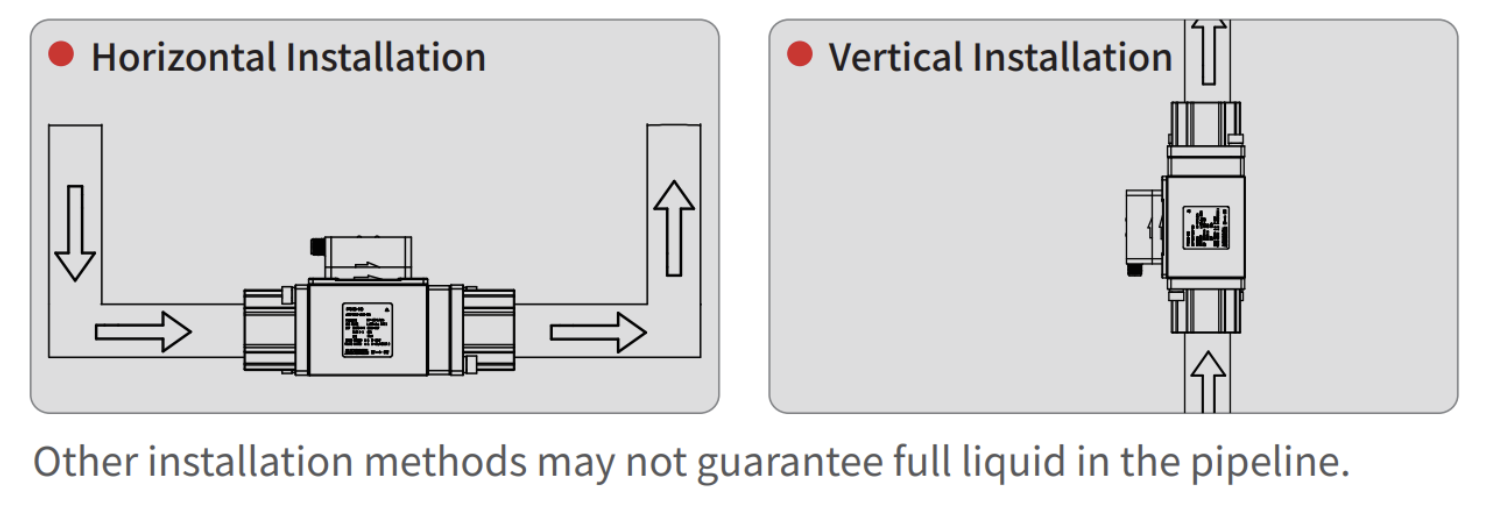

Compact & Efficient Design: The optimized structure minimizes bubble generation in the liquid and ensures a low pressure drop across the sensor, preserving system energy.

Output Flexibility: Supports multiple industry-standard electrical outputs for easy integration into existing control and monitoring systems.

Future-Proof Modularity: The modular design facilitates the addition of features as requirements evolve, protecting the investment.

Conclusion

The ADW FV Series vortex flow sensors combine proven physics with intelligent, adaptable engineering. They offer a precise, low-impact, and highly configurable method for liquid flow measurement, making them an ideal choice for applications in water treatment, chemical processing, HVAC, and general industrial monitoring where accuracy, reliability, and system integration flexibility are paramount.